JCM-V Series

| Model | Format Size (Inch) | Focal Length | Iris Range (F-stop) |

Focusing Range (m) | Mount | Field Angle(H×V) | Size(mm)(∞) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4/3 | 1.2 | 1.1 | 1 | 1/1.2 | 2/3 | 1/1.8 | 1/2 | 1/3 | |||||||

| LM5JCM-V | - | - | - | - | - | ● | ● | ● | ● | 5 | F2.8/F4/F5.6/F8 | 0.1〜∞ | C | 82.4×66.9 | Φ43×38.4 |

| LM8JCM-V | - | - | - | - | - | ● | ● | ● | ● | 8 | F1.4/F4/F8/F16 | 0.1〜∞ | C | 56.5×43.9 | Φ33×41.6 |

| LM12JCM-V | - | - | - | - | - | ● | ● | ● | ● | 12 | F1.4/F4/F8/F16 | 0.15〜∞ | C | 38.3×29.1 | Φ33×37 |

| LM16JCM-V | - | - | - | - | - | ● | ● | ● | ● | 16 | F1.4/F4/F8/F16 | 0.2〜∞ | C | 30.0×22.7 | Φ33×36.5 |

| LM25JCM-V | - | - | - | - | - | ● | ● | ● | ● | 25 | F1.4/F4/F8/F16 | 0.2〜∞ | C | 19.6×14.8 | Φ33×39.5 |

| LM35JCM-V | - | - | - | ◇ | ◇ | ● | ● | ● | ● | 35 | F2/F4/F8/F16 | 0.2〜∞ | C | 14.4×10.8 | Φ33×38.8 |

| LM50JCM-V | - | ◇ | ◇ | ◇ | ◇ | ● | ● | ● | ● | 50 | F2.8/F4/F8/F16 | 0.2〜∞ | C | 9.6×7.2 | Φ33×56.2 |

◇: Suitable

All products specificationsFeature

Kowa’s new JCM-V Series is designed for use in high vibration and shock environments.

With a design based on Kowa’s standard 2/3” JCM lenses, this new ruggedized megapixel lens series is ideal for applications that require increased durability and high optical performance.

- Equivalent to 2 megapixels performance

- Two way reversible nut is utilized instead of thumb

screws in order to tightly lock the focus adjustment ring in place. - Utilizing two way reversible nut contributes to the

prevention of screw dropping troubles.

-

Interchangeable Iris Plates

1. The JCM-V series uses interchangeable iris plates instead

of mechanical iris diaphragms with moving blades. You

can choose from four iris plates to adjust the F-stop.

-

Focus Adjustment Procedure

2. Unscrew the bottom ring of the outside body to adjust the focus to optimal position.

3. Screw the red two way reversible nut on the center body towards the bottom ring to lock in the focus.

Designed for Use in High Vibration and Shock Environments

JCM-V series is ideal for applications that require increased durability and high optical performance.

Application Samples

-

Forklift

-

Food Production Line

-

Conveyor Belt

-

Robot Arm

Risks Whilst Under Vibration and Shock Conditions

There are risks when using a general off-the-shelf lens whilst under vibration and shock conditions.

-

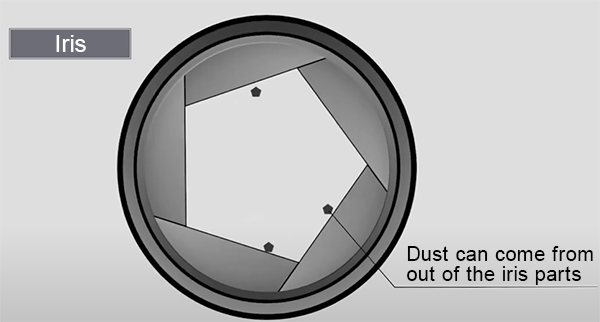

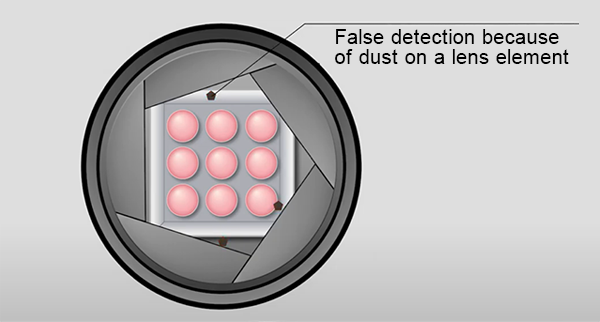

False Detection Caused by Dust

-

In the iris mechanism of a general off-the-shelf lens, dust can come from out of the iris parts by repeating iris sliding.

-

The dust on a lens element can cause a false detection.

-

-

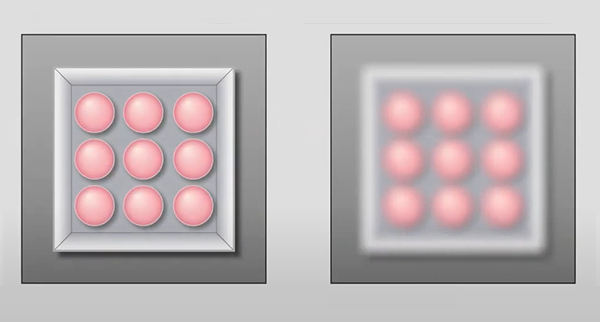

Decrease in Resolution Caused by Optical-Axis-Shifting

External factors such as vibration and shock can cause an optical-axis-shifting.

As a result, the resolution may decrease and the expected image may not appear.

-

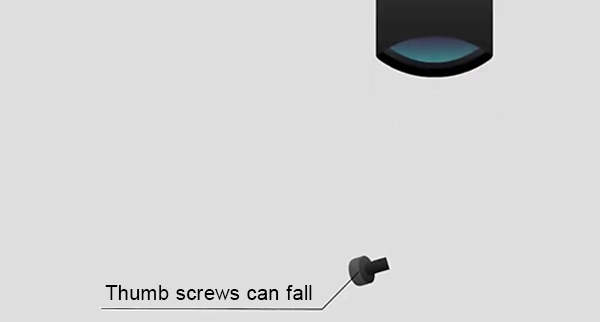

Multiple Losses Caused by Dropped Screws

General off-the-shelf lenses use thumb screws for iris and focus adjustment.

External factors such as vibration and shock can cause thumb screws to fall off,

which decreases in efficiency and safety in a production line.

JCM-V Series Solutions

-

False Detection Caused by Dust

1. Inter Changeable Iris Plate

Adjustment of F number can be done by just inserting a right interchangeable iris plate.

The plate minimizes a risk of dust falls rom iris parts to lens elements and keep clean condition. -

Decrease in Resolution Caused by Optical-Axis-Shifting

2. Glued Lens Elements and Mechanical Parts

Minimization of deviation in the optical axis whilst under vibration and shock conditions

by gluing the lens elements and mechanical parts. -

Multiple Losses Caused by Dropped Screws

3. Double Nut System

Elimination of thumb screws and use of a double nut system to tightly fix focus.

Low risk of loosening (lost focus) and falling parts. Lens design and body remains compact.

*To improve ruggedized performance, we recommend applying adhesive to each screw to prevent loosening.

Test Summary

*2 Compliant with JIC C 60068-27

*3 Compliant with MIL-STD-810G SHOCK

*4 The rest result varies depending on focal length. The values are only for reference, not guaranteed.

・ Test conditions: applying adhesive to each screw to prevent loosening.

Movie