Importance of Imaging Technology

The first step in image analysis is “accurate imaging”. Kowa Optronics places great importance on lens and camera selection, and the following points in particular are directly linked to the accuracy of analysis.

High-Resolution Lens

It is essential for reliably detecting minute scratches and foreign objects. Its high-resolution design enables clear imaging down to the finest details.

Low Distortion Design

Prevents errors in dimensional measurements, etc., and eliminates the need for software distortion processing.

Environmental Resistance Performance

Factories contain numerous factors that interfere with imaging, such as dust and vibration. Environmental resistance enables stable imaging even under such harsh conditions.

Preprocessing Technology

The captured images are pre-processed before analysis, which removes noise and adjusts contrast to improve analysis accuracy.

・Grayscale Conversion

・Filtering (Smoothing and Sharpening)

・Histogram Correction

・Mask Processing

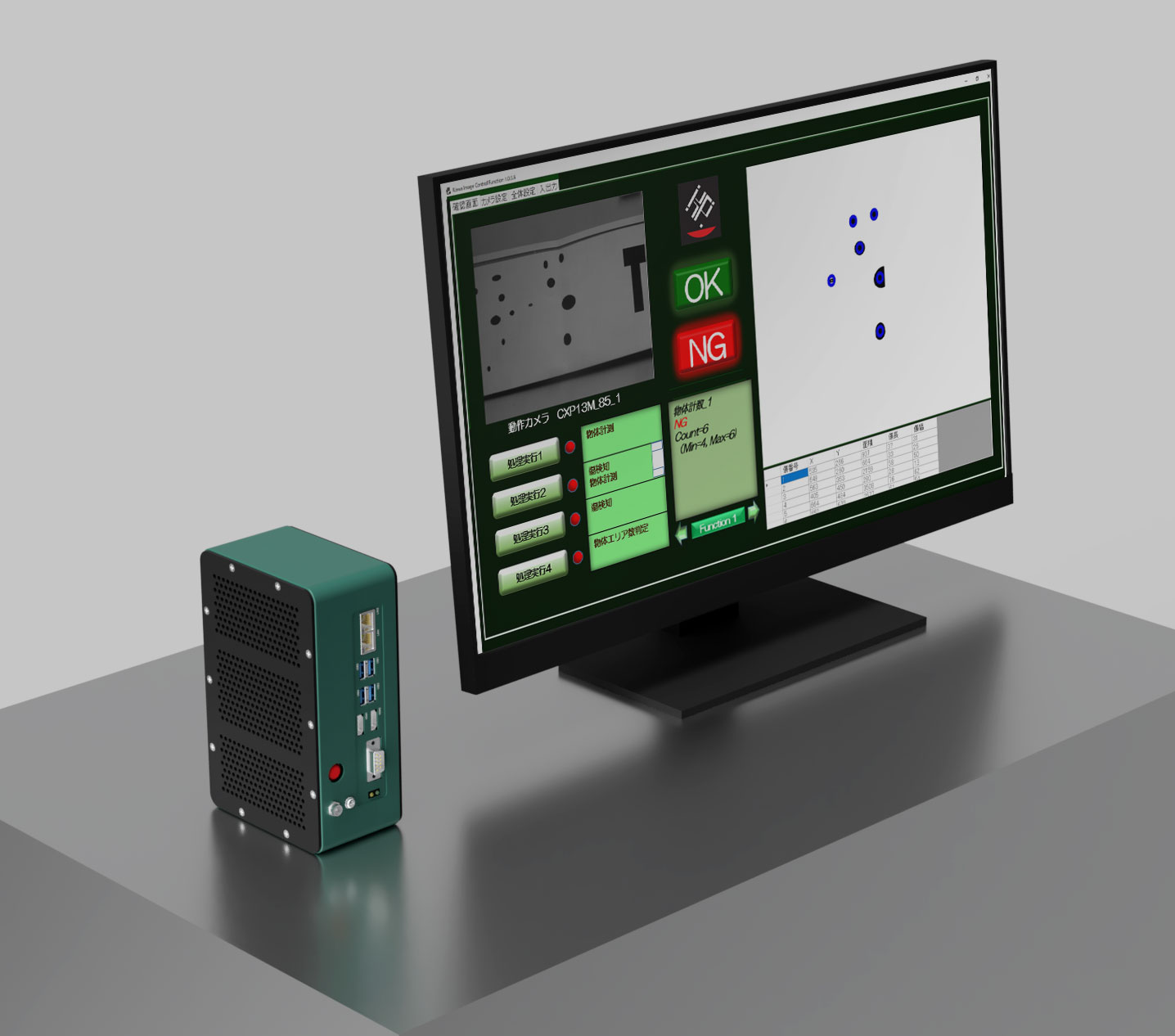

Kowa Optronics’ image processing unit (KP-VP series) can perform these processes in real time.

Feature Extraction and Analysis

This is the process of extracting meaningful information from images.

The KP-VP series enables the following types of analysis:

Edge Detection:Extracting scratches and contours

Shape Recognition:Determining the presence or absence, and orientation of parts

Pattern Matching:Determining whether an image matches a registered image

AI-OCR:Character recognition while correcting faint or missing characters

Judgment/Classification

Based on the extracted features, products are judged as pass/fail and classified, and a wide range of inspections are possible, including:

・Determination of good/defective products

・Detection of foreign object contamination

・Dimensional acceptance/rejection judgment

・Printing accuracy verification

Furthermore, it is equipped with a system that immediately detects abnormalities.When a defect is detected, an alert is sent, allowing for swift countermeasures to be taken. In addition, parts that are judged to be “abnormal” are displayed on a heat map, making it possible to visualize processing defects. This allows you to identify problem areas and minimize the occurrence of defective products.

Output and Linkage

The analysis results are output to a PLC, robot, or host system and reflected in the next process.

Supports interfaces such as GigE and CoaXPress , allowing for flexible system construction.

Application Examples

Food Factories:Inspection of printing on packaging films

Pharmaceuticals:Inspection of tablets for foreign matter

Logistics:Reading barcodes on slips

Automotive parts manufacturing:Detection of chipped cutting edges

Summary

Image analysis is not simply image processing, but an advanced technology that combines optical technology, AI, and control technology. Kowa Optronics provides lenses, cameras, and image processing units as a complete package, enabling us to realize optimal analysis solutions for each site.