What is a vision processor?

A vision processor is a device that analyzes images captured by a camera in real time to inspect, recognize, and judge products. Kowa Optronics’ vision processor

“KP-VP series” enables advanced image recognition using AI .

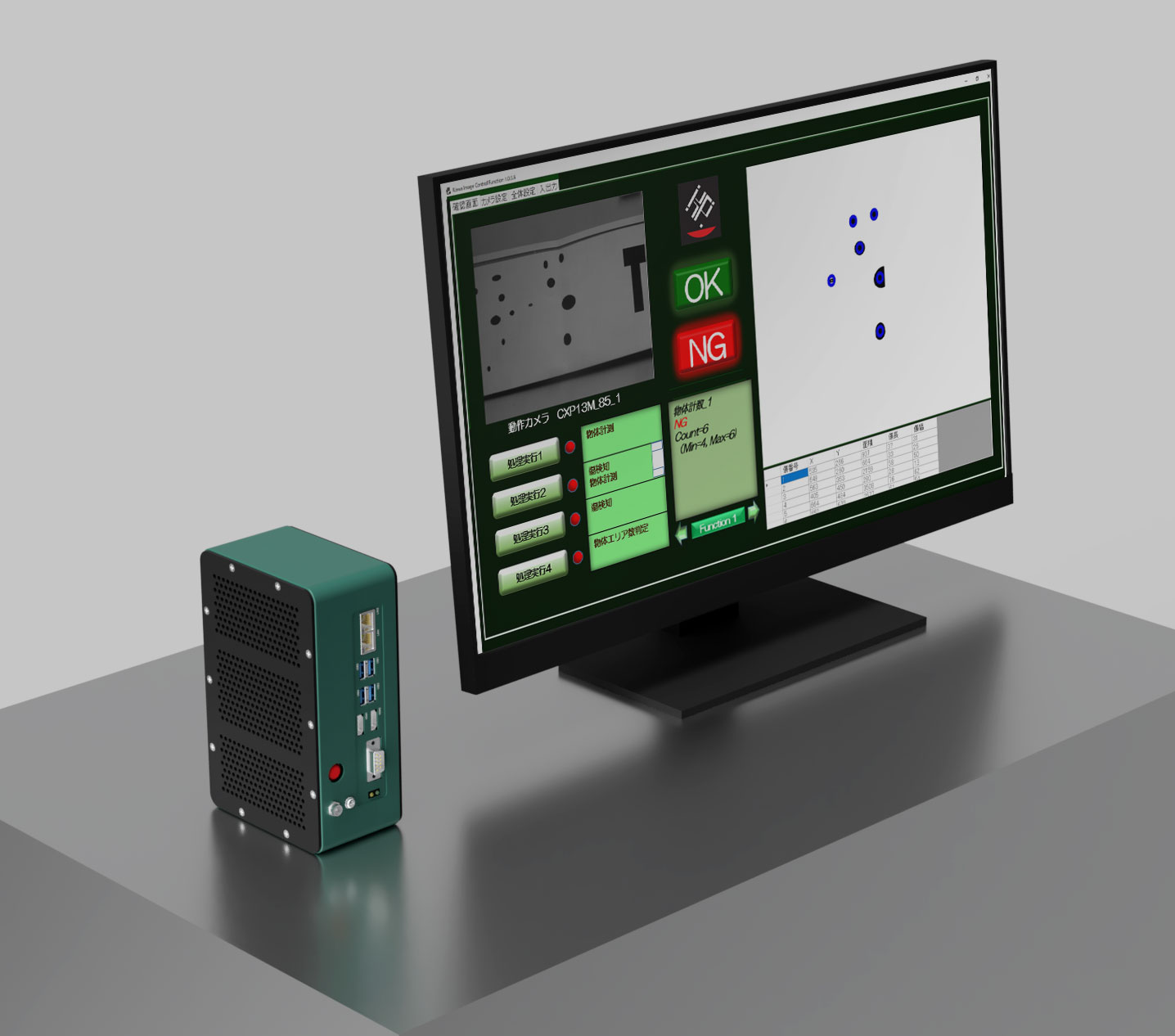

Types of processing technologies

Rule-based processing

This is a conventional image processing technology that judges based on clear criteria such as thresholds, shape, and color.

It allows for high-speed processing and is suitable for simple inspections.

AI processing (deep learning)

By learning from sample images, complex patterns and subtle anomalies can be detected with high accuracy.

Even small scratches and foreign objects can be recognized in 0.3 to 0.4 seconds.

Main functions and usage scenarios

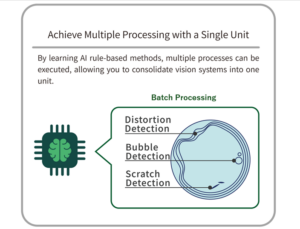

Defective product judgment

Automate visual inspection with AI. Significantly improve the quality and speed of work in visual inspection of products and raw materials.

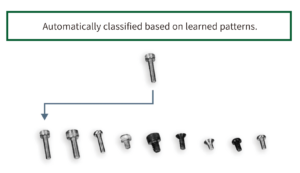

AI classification

Classification judgments can be made by learning several patterns and shapes to be classified.

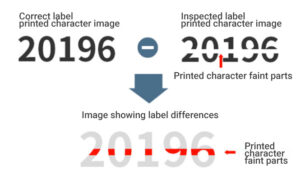

AI character recognition (AI-OCR)

Improves recognition rate while correcting missing or faint print. Also supports cylindrical and oval containers.

Label and slip reading

Contributes to ensuring traceability in the logistics process. Also supports print inspection and code reading.

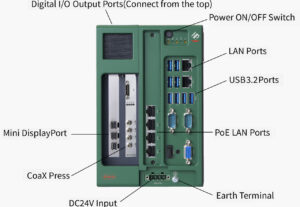

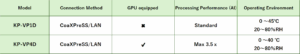

Example of product specifications ( KP-VP series)

KP-VP1D

KP-VP4D

Vision Processor | Kowa Optronics Co.,Ltd.

Connectable cameras and peripheral devices

・Compatible with GigE cameras, CXP cameras, etc.

・When combined with an environment-resistant camera, it operates stably even in certain oil, water, and dusty environments.

・External control is also possible via the USB- connected I/O unit

Summary

Vision processors are core technologies that support ” intelligent transformation of work sites” by integrating AI and optical technologies.Kowa Optronics’ vision processors are compatible with a wide range of applications, from general-purpose to specialized inspections, and contribute to improving quality and efficiency on the manufacturing floor.