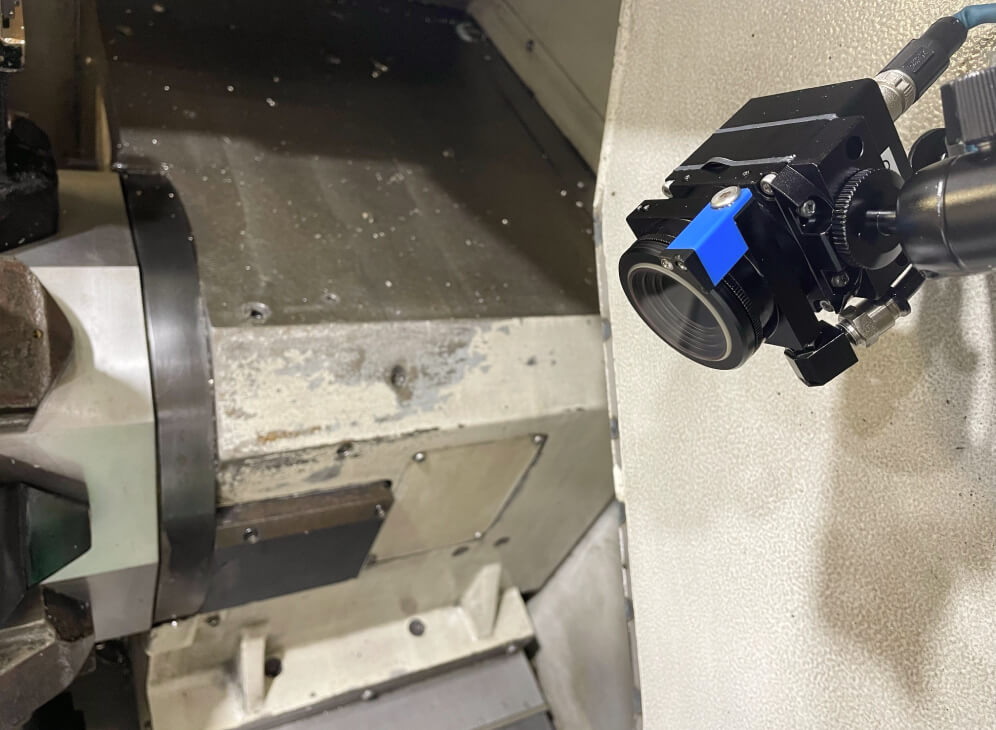

Camera for

Inside Machine Tools

AI Image Processing

"AI" detects unexpected situations inside machine tools!

- Processing

Error - Chip

Wrapping - Cutting/Drilling Tool

Edge Chipping

- Processing

Error - Chip

Wrapping - Cutting/Drilling Tool

Edge Chipping

AI Detection Improves Work Efficiency

AI detects common problems that machine tool users face.

AI detects conditions within machine tools that could hinder production during machining.

By addressing the issue before it becomes a serious problem, it contributes to improving work efficiency.

-

01Visualizing

"processing defects"RW Series

(Vision unit camera

with Rotary Wiper)Vision Processor

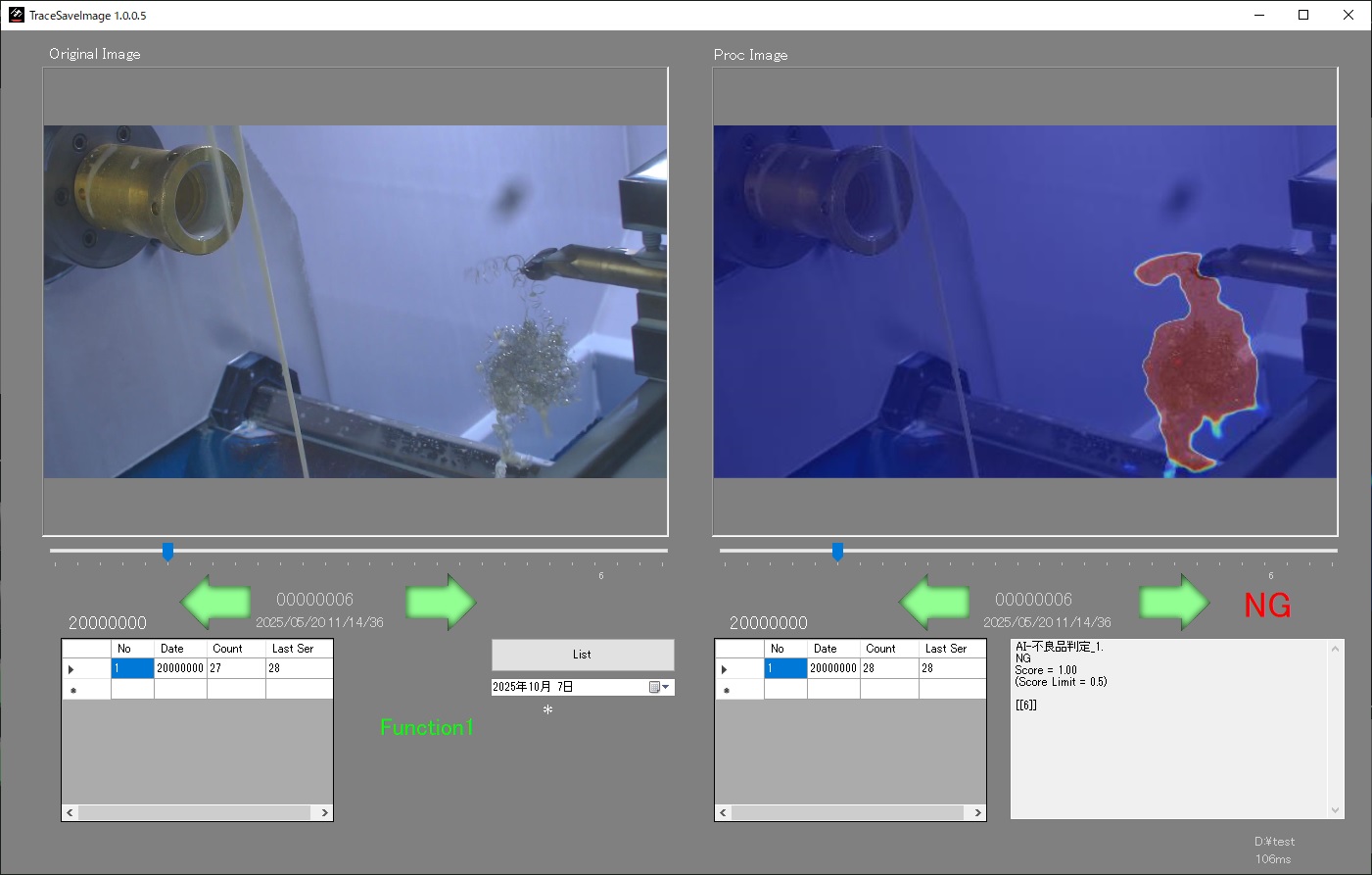

By combining it with a vision processor, it enables to use AI functions to detect abnormalities. Areas judged to be "abnormal" are displayed as a heat map, making it possible to visualize machining defects.

-

02Detects and notifies of wrapping of chips

RW Series

(Vision unit camera

with Rotary Wiper)Vision Processor

By combining it with a vision processor, it can send out alert information when a defect occurs, minimizing the occurrence of defective products.

-

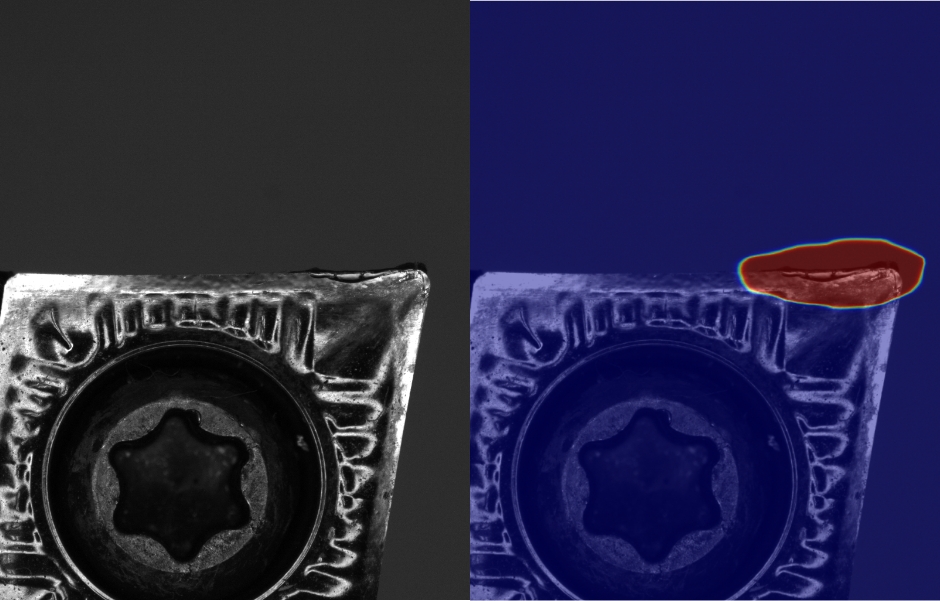

03Detects tool's chipped cutting/drilling edges

RW Series

(Vision unit camera

with Rotary Wiper)Vision Processor

By combining it with a vision processor, it can detect abnormalities such as broken or chipped tools.

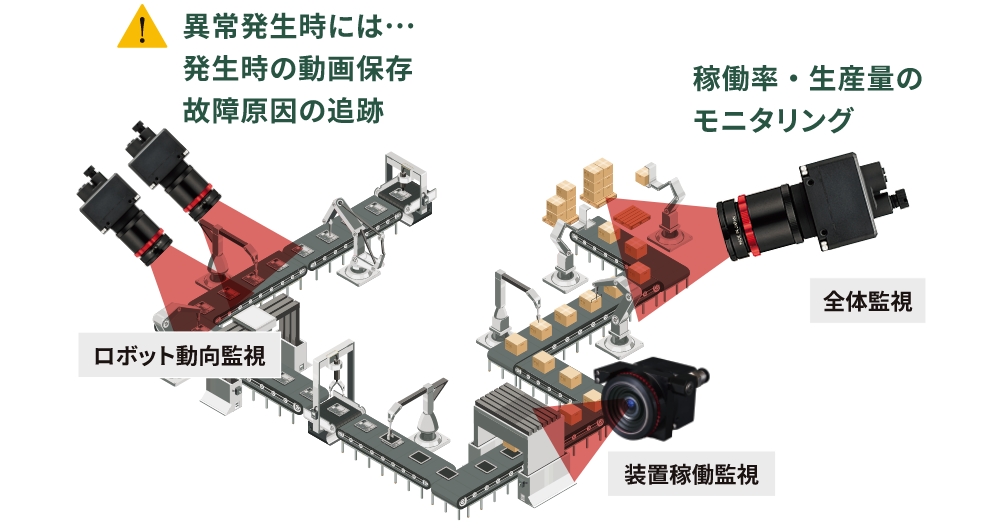

Monitoring Function Improves Work Efficiency

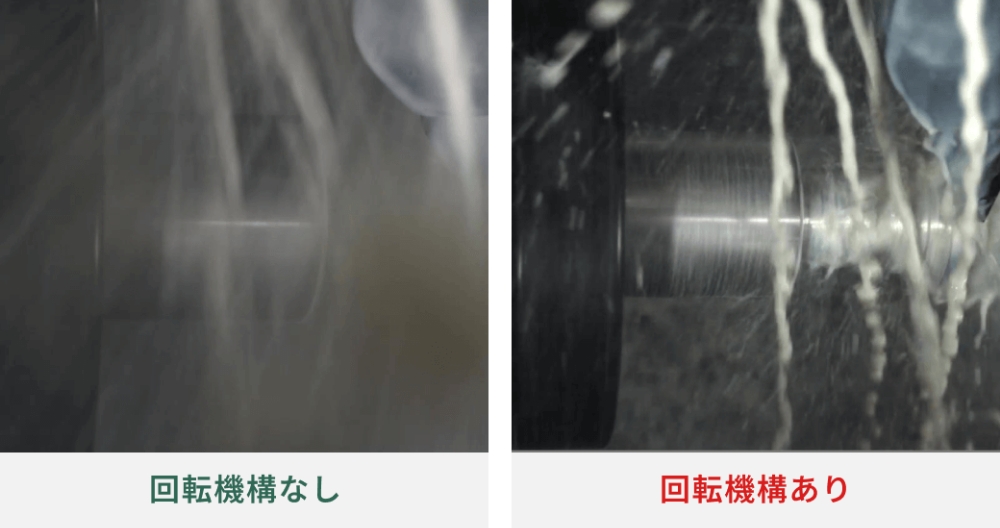

Delivering clear visibility even in environments where water and oil spray.

The "Vision Unit with Rotary Wiper" solves the challenges of monitoring machine tools, such as situations that have previously been given up on, such as the coolant environment or blind spots of the camera, as well as defects caused by unexpected problems.

-

Achieve clear vision

Maintains a clear view even while workpieces are being processed on the machine tool.

-

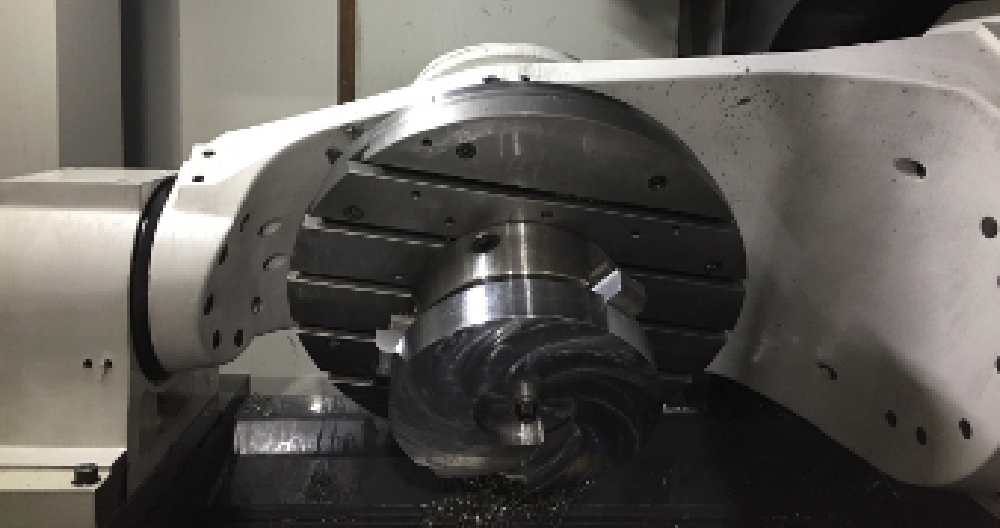

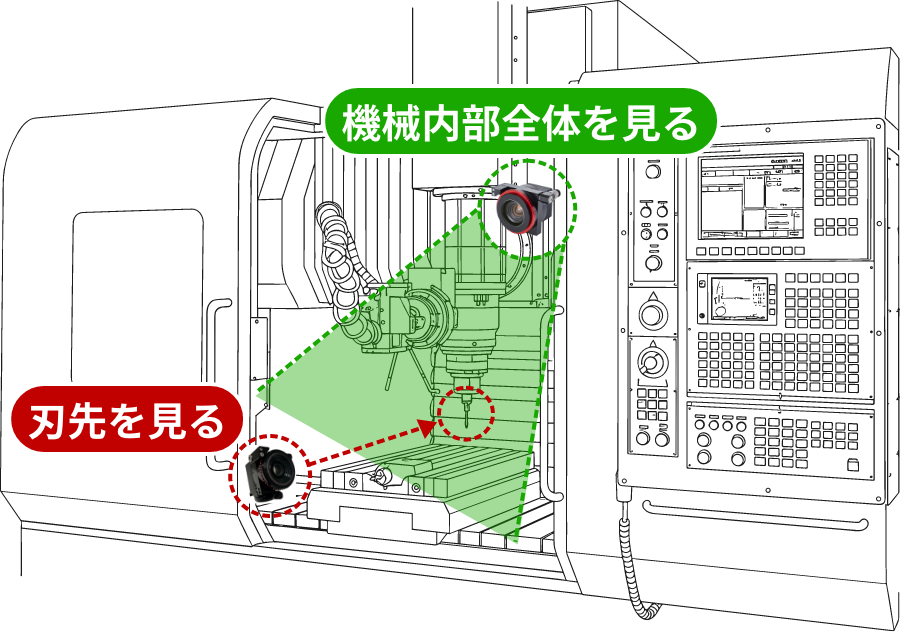

Monitoring inside of

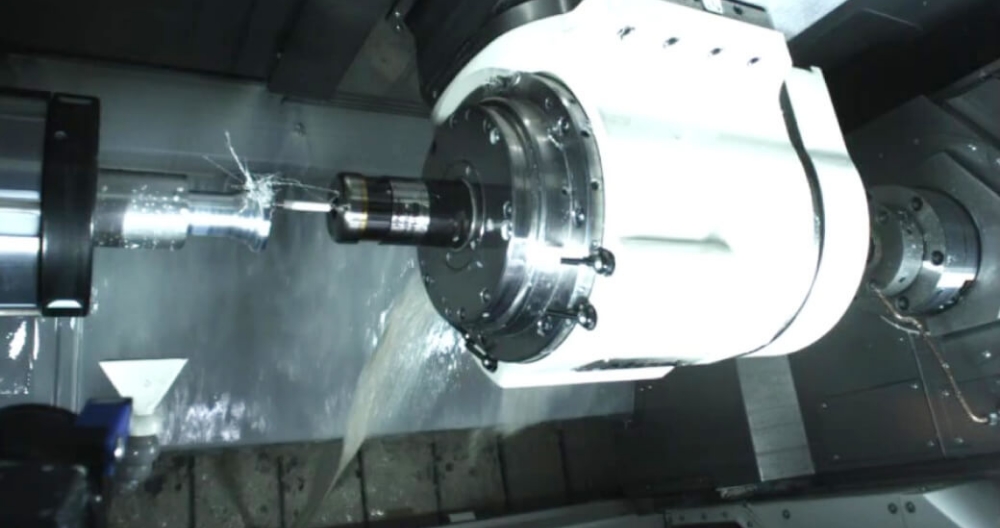

a machine toolIt keeps coolant and chips out and clearly captures the inside of machine tools such as lathes, milling machines and cutting machines.

-

Can be installed in blind spots

Compact size allows it to be installed in places where it was previously impossible to install. Real time monitoring of the processing status allows for smooth reviews of the process.

-

RW Series

(Vision unit with Rotary Wiper)

+ NVR

Recording of the process and data analysis are possibleBy recording the machining process, you can review it over and over again, even in places that were previously difficult to check. This is useful for identifying the cause of any defects that may occur.

-

RW Series

(Vision unit with Rotary Wiper)

+ NVR

Remote real-time monitoringReal-time monitoring allows you to detect unexpected problems in advance and avoid having to stop the production line.

-

RW Series

(Vision unit with Rotary Wiper)

+ NVR

Visualizing the entire "operating status" from overall monitoring to monitoring inside the machine tools.By combining it with a vision processor, its AI functions can detect abnormalities. Areas judged to be "abnormal" can be displayed as a heat map, making defects visible.

*NVR = Network Video Recorder

With KOWA,

you can

select the best solution

for your environment.

-

Up to 45 camera + lens combinations possible

-

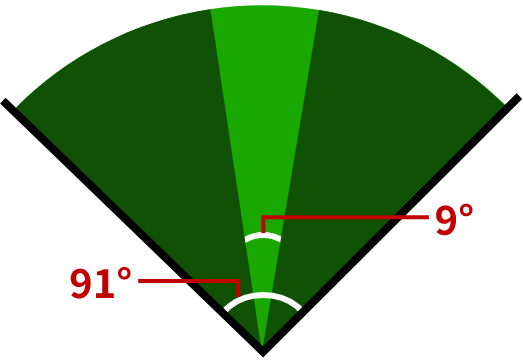

Covers a horizontal field of view (9°to 91°)

By changing the lens, you can select the horizontal angle of view from wide 91°to narrow 9°. Choose from five different lenses to suit your required field of view.

Horizontal field of view: 9° to 91° -

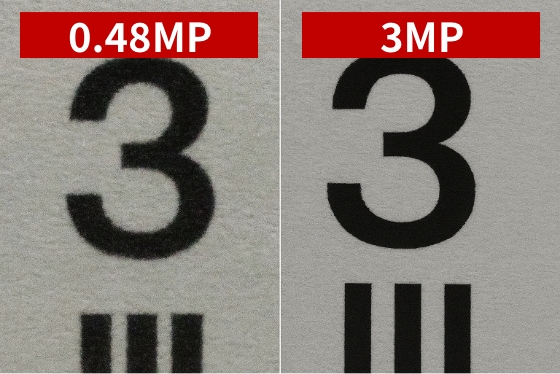

Resolution can be selected from 0.48MP to 3MP

You can select the optimal resolution for your application.

Selectable resolution

0.48MP/1.3MP/2MP/3MP Resolution image

-

The mounting position can be changed

Lens and cameras can be freely combined, allowing installation anywhere inside the machine, supporting highly accurate inspection and monitoring.

Unique Structure

Ensuring Clear Vision

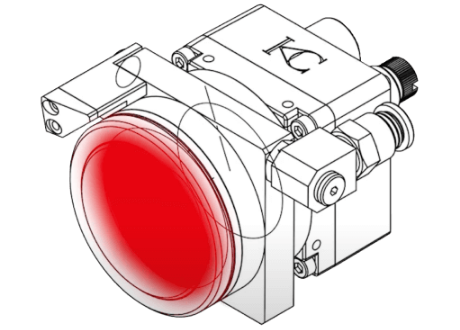

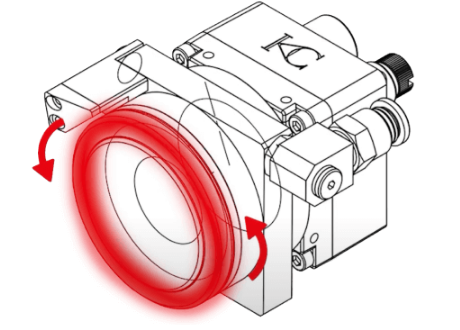

Unique structure that rotates the protective window glass by supplying compressed air. Prevent water droplets and oil from adhering to the front of the window glass!

-

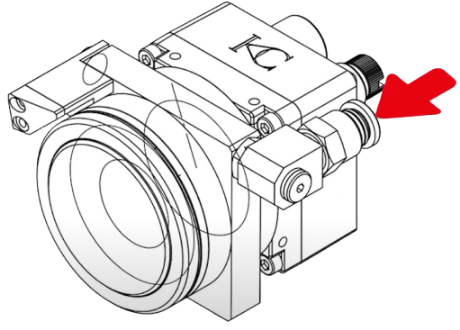

Air nozzle

The exhausted air is used to remove liquids that cannot be removed by the centrifugal force of the rotating window.

-

Waterproof and oil-resistant camera

Lens of a selected focal length can be attached

-

Supply air

Positive pressure inside the housing makes it waterproof and oil-resistant

・Air pressure used :

0.05MPa to 0.1MPa

・Air flow rate : 15 to 20 liters/min. -

Environmentally resistant camera housing

-

Rotating window glass

Air pushes the built-in fins to rotate, removing the liquid with centrifugal force.

-

Water- and oil-repellent coating

Scratch-resistant sapphire glass with water- and oil-repellent coating -

Air supply

High-pressure air rotates the front glass at high speed -

High-speed rotation

High speed rotation removes water and oil residues

Testimonials from Implementing Organisations

SK Mechanics Co., Ltd.

Customer details

- Representative Director

- Wataru Sashida

- Head office location:

- Iruma, Saitama, Japan

- Founded

- October 1991

- Business Activities:

- Vacuum equipment parts (chambers), LCD/solar cell, panel manufacturing equipment parts, capacitor manufacturing equipment, semiconductor inspection equipment and other equipment parts

- What were the challenges facing your company?

- Our company manufacture metal parts, high-precision processing, and friction stir welding, processes metal parts using various machine tools, but it is not possible to clearly see what is happening inside the machine from outside while the workpiece is being processed, and we were unable to check the finished product until the process was complete. For this reason, we wanted to be able to check the status of the tools and workpieces during processing.

- What made you decide to introduce a vision unit with a Rotary Wiper?

- First of all, we were able to see clear images even when coolant was splashing on the workpiece. It was also a great help that we were able to have a demo set up before purchasing. Images taken during the demo set up confirmed that splashed coolant was being removed and that the machining status could be monitored in real time. Furthermore, it is possible to save images as records on an NVR, which can be reviewed at a later date, so we decided to introduce it as we felt it would be effective from the perspective of traceability.

- Please let us know if you notice any effects points after implementation.

- We decided to install the system because it allows us to see and record the machining status, but we are also considering using it in a different way than we have used it so far. That is for employee training. Senior employees can teach new employees and employees who are using the equipment for the first time how to operate the equipment and how to set up the workpiece while watching the recorded data, so we hope that this will deepen their understanding of the equipment and improve work efficiency. At the moment, we have not installed it on all of our multiple pieces of equipment, but we would like to positively consider installing it on additional machines.

Providing careful support through to implementation

Here is an example of the process after your inquiry.

We will flexibly accompany you through to the actual operation, tailored to your specific circumstances.

-

Inquiry

Our staff will contact you quickly after receiving your inquiry.

-

Hearing

We will listen to any issues you are facing. Please feel free to tell us about your current situation and tasks.

-

Verification

We will conduct a sample evaluation (verification) using the images you wish to process.

*You may be asked to provide several sample images.

-

Proposal

We will report the results of the verification and propose solutions to resolve the issues.

-

Installation/Adjustment

During installation, we conduct operational tests while meticulously checking that no issues have arisen on the production line.

-

After-Sales Support

We will respond to the changes or concerns you may have after the implementation.

About Kowa Optronics

With our experience and achievements as a lens manufacturer, we are at the forefront of machine tools and optics.

Kowa Optronics is a total solution supplier capable of in-house manufacturing and sales of cameras and image processing equipment, leveraging the experience and expertise cultivated as a lens manufacturer.

Specifically, Kowa Vision Systems offers models featuring environmental resistance (waterproof, dustproof, oil-resistant) built upon vibration and shock resistance, delivering outstanding performance even in harsh environments.

-

Extensive lineup

There are over 5,000 possible combinations of lenses and cameras. We will propose the optimal specifications for you from our extensive lineup.

*Many other options are also available, such as housings and covers with lighting. -

Customization suggestions also available

We have established a system that allows us to handle everything from development to manufacturing and support in-house, all in one place. We can also customize and propose products according to your specifications and needs. Please feel free to contact us for more information.

-

Pursuing total solutions

We develop and manufacture our own lenses, cameras, and image processing equipment, and with this wide range of capabilities, we can provide total solutions to the various challenges our customers face.

Q&A : Frequently asked questions

- Want a product catalogue or spec sheet?

-

You can download it from our website by registering as a member there.

- Is there an SDK available?

-

It is provided free of charge and can also be downloaded from our website by registering as a member.

- Please tell me about the delivery time.

-

Most cameras and lenses are available for immediate delivery. For details, please contact our branch or sales office or visit our website.

- Do you do customized products?

-

We can handle everything from semi-customization to full customization. As we develop and design both cameras and lenses in-house, we have the strength to handle any customization, so please feel free to contact us.

- What are your implementation results?

-

Robot vision systems and industrial vehicles subjected to strong vibration/shock, installations in the food industry and processing machinery where water and oil splashes are common, and dusty plant environments. Additionally, we have extensive experience in installations on manufacturing equipment, inspection on production lines, measurement, and more.

- Is there a support system?

-

We have a dedicated support team. We will assist you with sincerity and dedication.

- It says oil resistant, but what types of oil is it resistant to?

-

We conduct tests using multiple cutting oils. Please contact us for details.

- Does the rotating mechanism of the Rotary Wiper need a power source?

-

No, but air supply is required (approx. 0.1 MPa).

Please feel free to contact us anytime.

Contact Us

Kowa's Perspective

The products that SK Mechanics introduced this time were our "Vision Unit with Rotary Wiper," which combines a conventional vision unit with a housing equipped with a special mechanism to remove away dust and liquid on the glass window surface, and a "Network Video Recorder (NVR)" with recording functionality. These products have been proposed to customers as products that allow them to view and record the machining status inside machine tools in real time, but we were able to realize that there are other ways to use them, such as with SK Mechanics Co., Ltd.

This product has undergone numerous design and development processes before it was released. Please feel free to contact us with any concerns you may have. We encourage you to first apply for a demo installation and try it out in your own environment.