-

CASE 1

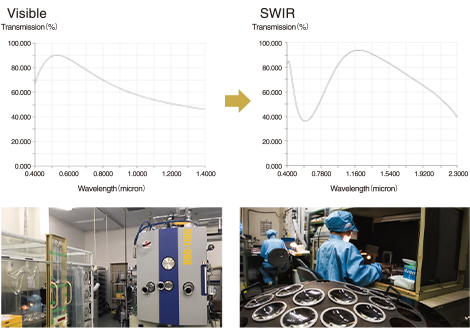

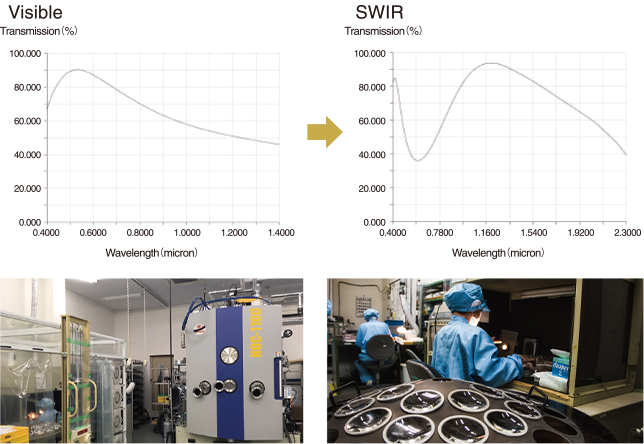

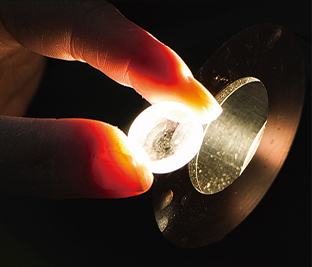

Improving the transmission or sensitivity.

-

CASE 2

Reducing the risks of failure when using lenses on manufacturing and inspection lines.

-

CASE 3

Designing a smaller or compact lens.

-

CASE 4

Creating the best camera and lens combination.

CASE1

Improving the transmission or sensitivity.

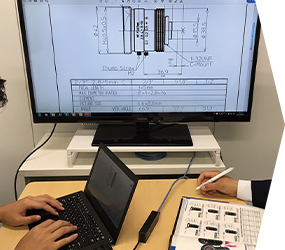

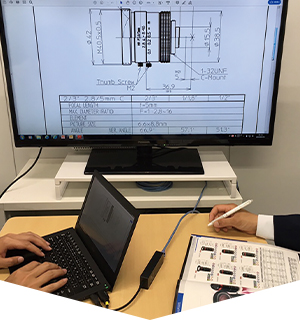

CASE2

Reducing the risks of failure when using lenses

on manufacturing and inspection lines.

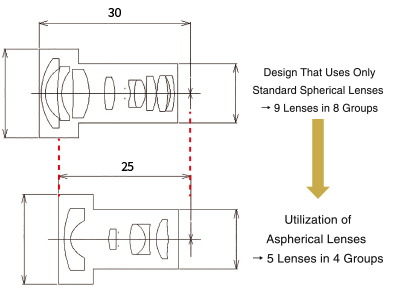

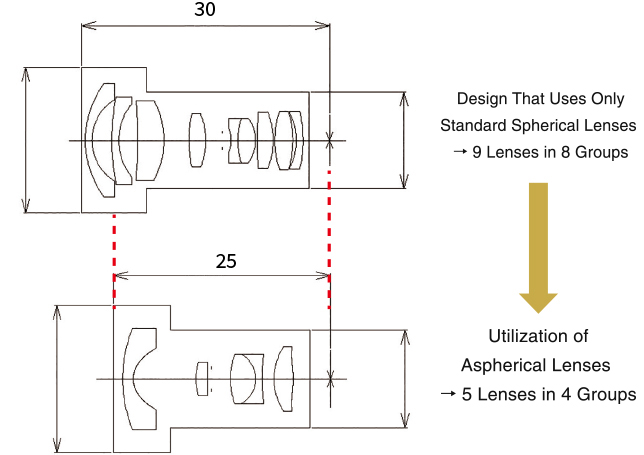

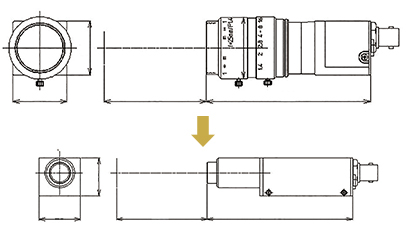

CASE3

Designing a smaller or compact lens.

CASE4

Creating the best camera and lens combination.

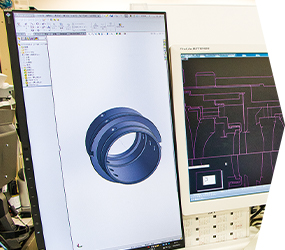

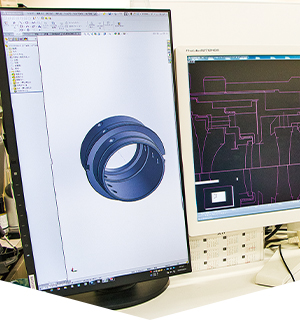

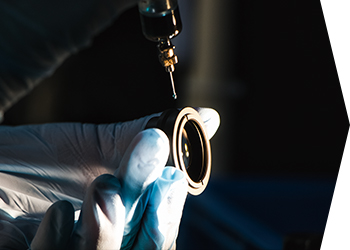

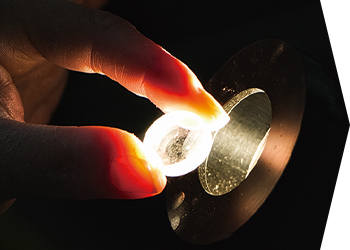

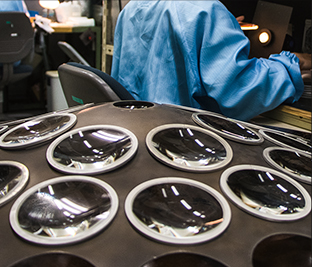

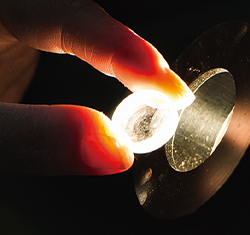

From semi-customized to fully customized lenses!

Kowa can design and manufacture original lenses

from only one unit!