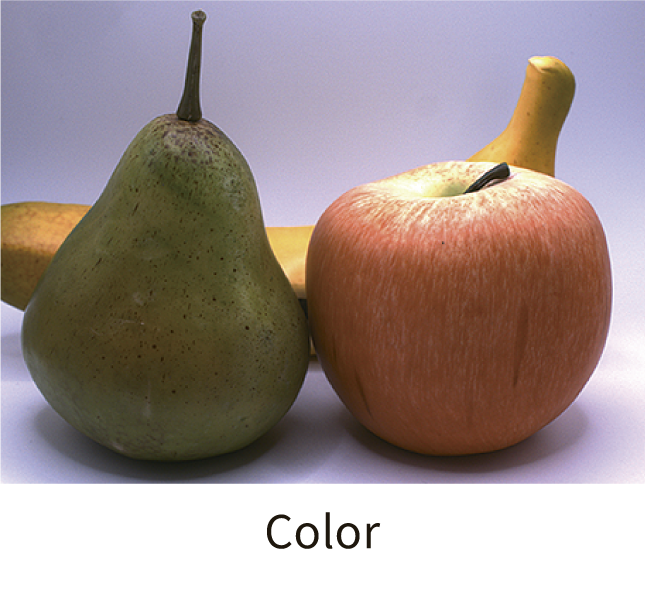

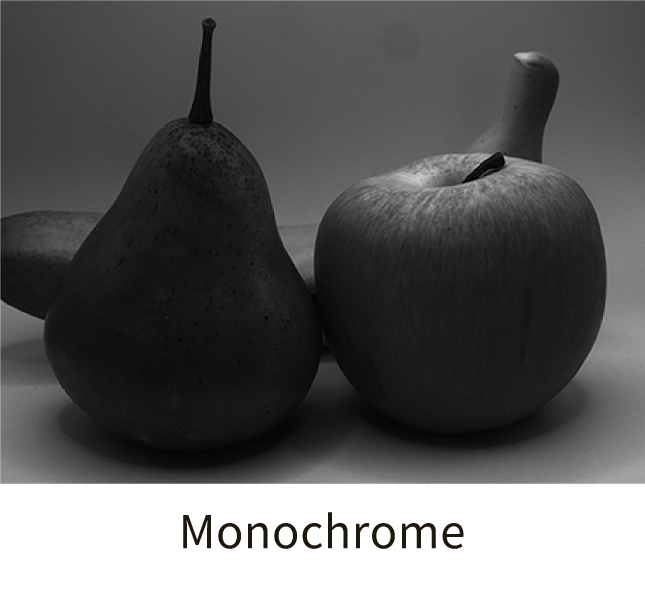

Color and monochrome

If you need to identify by color information, use a color camera; if you do not need color information, use a monochrome camera. In general, monochrome cameras are more highly sensitivity than color cameras , providing advantages in adjusting shutter speed and depth of focus.

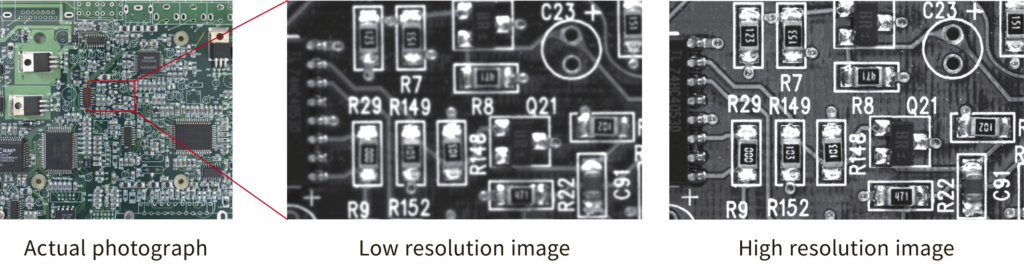

Number of pixels

The camera is equipped with an image sensor, the number of pixels of which is determined by the image sensor. Selecting a camera with a high pixel count makes it possible to perform more detailed inspections.

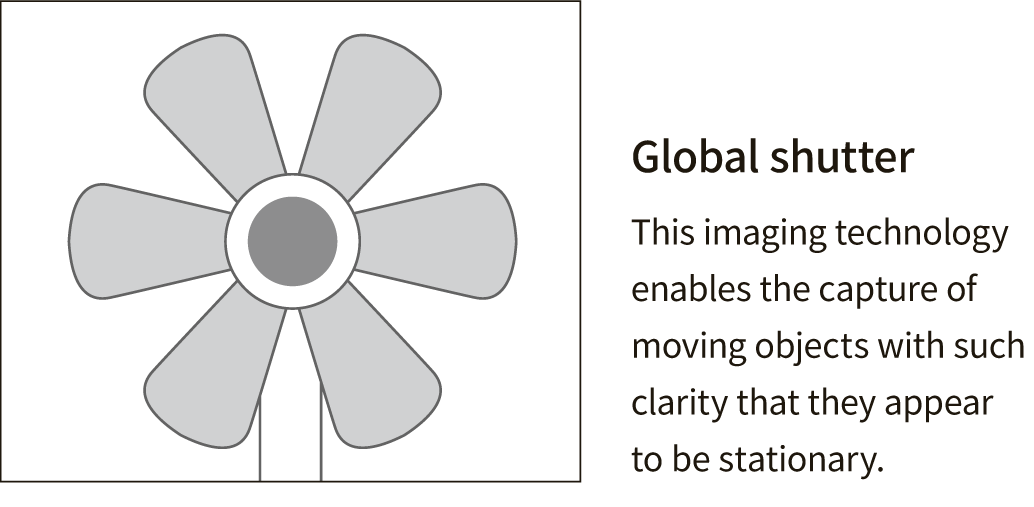

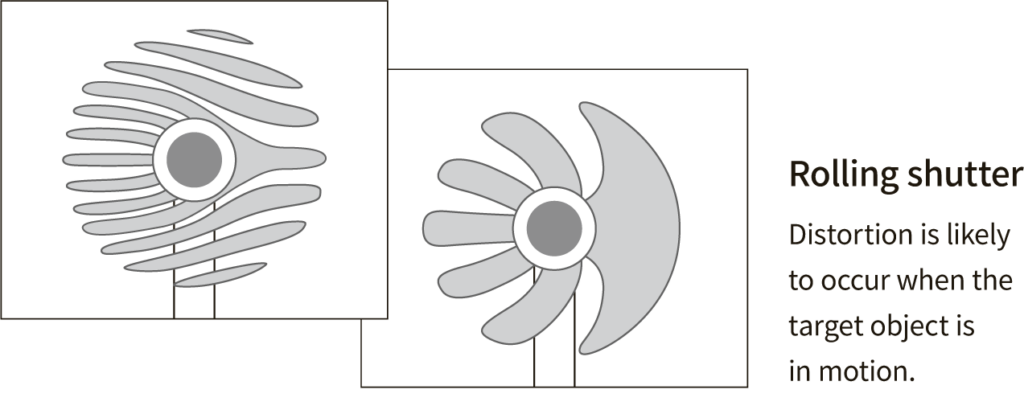

Shutter Systems

There are two types of image sensors: the global shutter system and the rolling shutter system. In the rolling shot method, each line on the image sensor is exposed sequentially, so the exposure timing differs for each line, causing distortion of the image when the object is moving, which is called the rolling shutter phenomenon. In contrast, the global shutter system exposes all pixels at the same time, so this distortion does not occur. (The global shutter system is necessary for accurately imaging moving objects.)

Frame rate

Frame rate is the number of images that can be output per unit of time, which is generally expressed in terms of the number of images per second [fps]. Frame rate is the number of images that can be output per unit of time, which is generally expressed in terms of the number of images per second [fps]. The higher the camera spec fps, the shorter the data transmission time. A higher frame rate also means that more images can be sent in a shorter period, making it possible to continuously capture fast-moving objects. In addition, the shorter the time to output one image, the less time it takes to start image processing at a later stage, leading to a shorter tact time

About Industrial Camera Interfaces

One of the most important factors when selecting cameras is the interface of the camera. The industrial camera interface has the role of connecting the camera to the computer to transfer the captured data into the image processing software. The higher the number of pixels in the image sensor, the larger the amount of data per image, so a camera with a high frame rate requires a correspondingly high-bandwidth camera interface. Currently popular camera interfaces include GigE, CoaXPress, USB3 Vision, and CameraLink. Each of these interfaces differs in terms of transmission speed, number of cameras connected, cable length, etc. Selection should be made in consideration of the installation environment as well as the purpose and application.

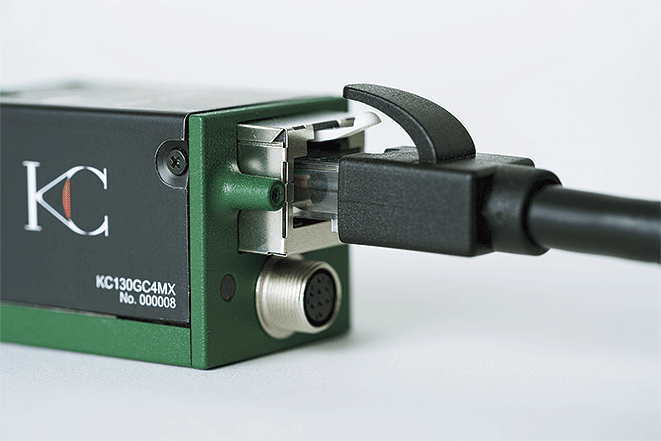

GigE(Gigabit Ethernet)

GigE provides high-speed data transfer over long distances of up to 100 meters using standard Ethernet cables and can be connected directly with most PCs, without the need for additional hardware. Another advantage is that multiple cameras can be used on the same network. However, high-speed data transfer requires high-quality cables and can be complicated to set up.

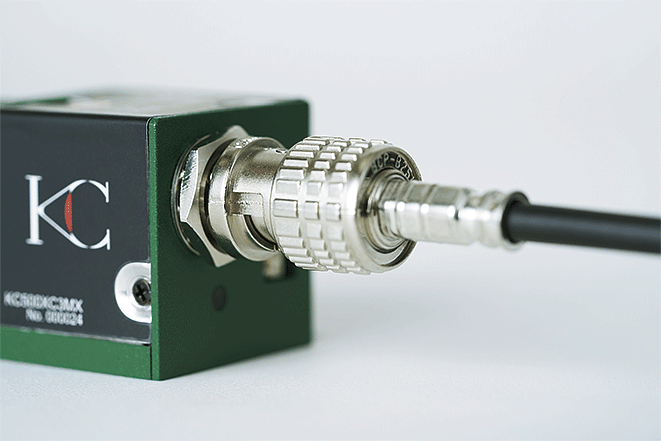

CoaXPress

CoaXPress allows high speed data transfer up to 12.5Gbits/s over coaxial cable, allowing data transfer over long distances (up to 100m or more), and high speed real-time triggering. However, it requires a dedicated frame grabber, and the cables and connectors can be proprietary and expensive.

USB3 Vision

Since USB3 Vision uses USB ports, it can be connected directly to most PCs, making it easy to plug-and-play. In addition, high-speed data transfers of up to 20 Gbits/s are possible. However, the cable length is relatively short (up to 5 m) and power supply may be limited during high-speed data transfer.

CameraLink

CameraLink offers fast and reliable data transfer and supports real-time triggering. In addition, it offers a wealth of additional features and options. However, it requires a specific frame grabber, requires short cable lengths (up to 15 m), and can be complex and expensive to setup.

Dustproof and waterproof

Dust and water resistance is required in environments where the product is exposed to water or fine dust generated from paper, thread, etc. Our dustproof and waterproof standard is based on IP67, but oil-resistant products are also available. While some cameras and lenses are waterproof and dustproof by themselves, some products are waterproof and dustproof using a camera housing.

About IP standards

IP stands for “Ingress Protection” meaning the degree of protection against the ingress of external solids and liquids; in the case of IP67, the first number “6” is the degree of protection against dust and dirt, meaning it is completely dustproof. The next number “7” is the water protection rating, meaning the product is protected against temporary submersion. Thus, it indicates that the product can be used safely even in harsh environments.

Summary

The selection of a camera for FA is an important factor directly related to achieving success in image processing inspections. You must choose the best camera considering points such as the choice between color and monochrome, pixel count, shutter type, frame rate, camera interface, and dust/waterproof performance.